The can sealing machine series covers all aspects, helping the industry achieve high-quality development.

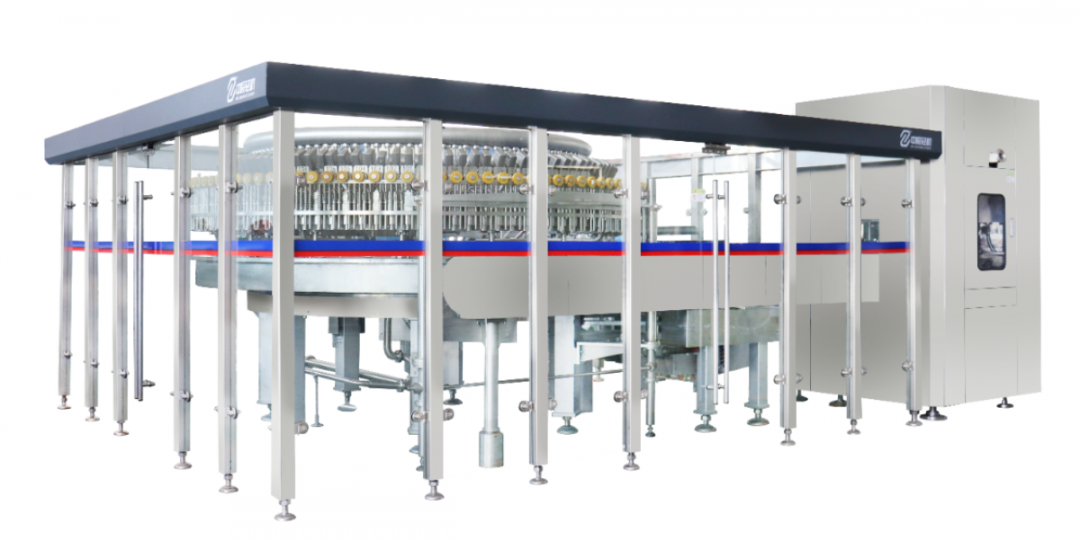

In recent years, the market for metal thin-walled cans and related products for food and other products has shown a rapid growth trend. Zhongchen Light Machinery has targeted this trend and established a professional can sealing machine business team to continuously increase its R&D investment in the field of can sealing machines for metal thin-walled cans. It has overcome a number of technical difficulties in the field of can sealing machines and has designed and manufactured a full range of can sealing machine equipment for beer, beverages, milk powder, and food products of all categories and industries, achieving a production capacity of 6,000 to 110,000 cans per hour. It has created a series of can sealing machine products with world-advanced level that are owned by Chinese people. Combining Zhongchen Light Machinery's advanced full-electronic valve beverage filling technology, sterilization technology, palletizing and secondary packaging technology, and conveying system technology, it has achieved complete independent design and construction of full-speed series beverage packaging container filling and packaging production lines, injecting new vitality into the industry and bringing real quality and cost benefits to customers.

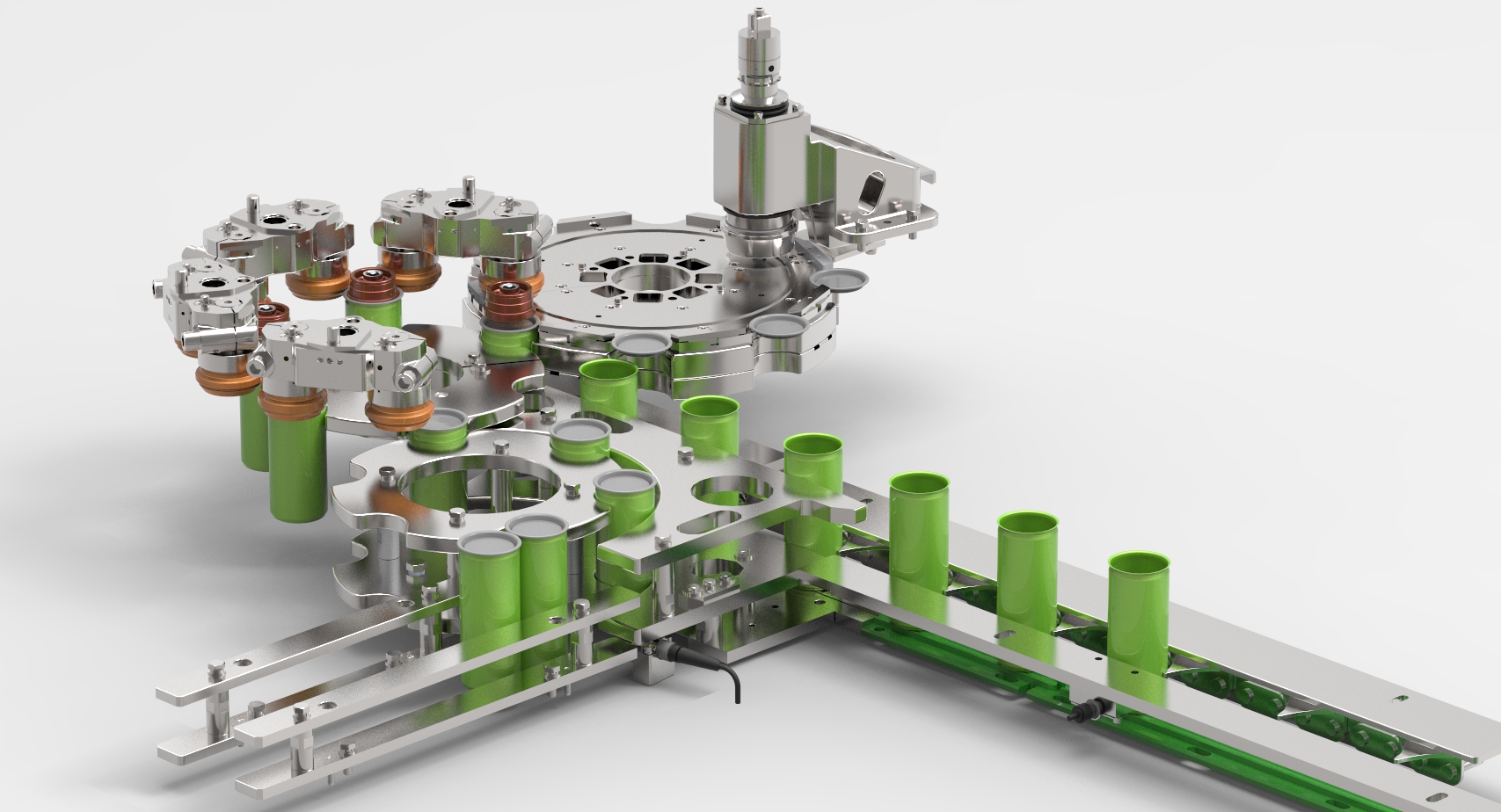

The high-speed seaming machine has a fully stainless steel construction for the seaming area, which is suitable for various cleaning environments and meets higher hygiene requirements. The fully automatic closed-loop wheel lubrication system enables continuous operation for 24 hours and has reliable pressure and flow monitoring, making the equipment run more safely and reliably. The modular design of the changeover parts, combined with the automated one-click lifting program, meets the needs of more flexible production lines, making the changeover work more efficient and quick. The automatic circulation lubrication of the entire machine achieves low-cost maintenance of the equipment.

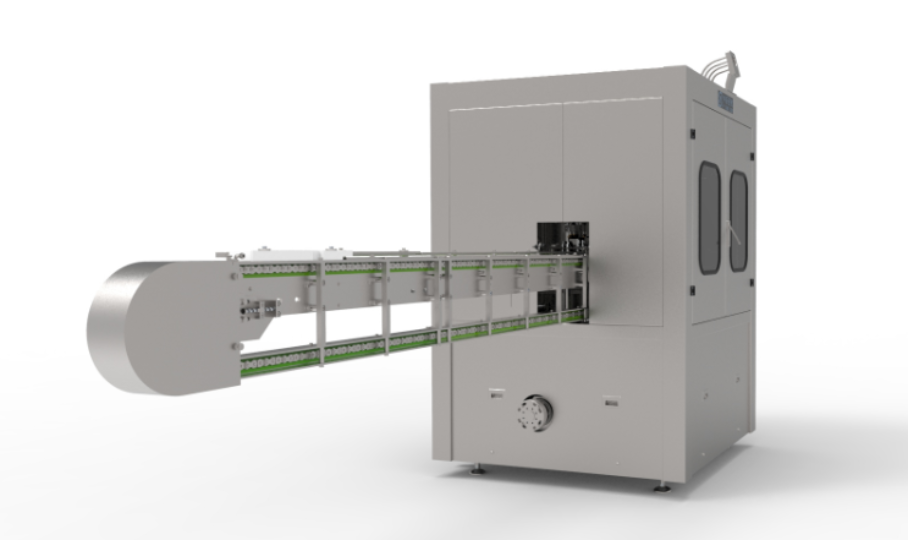

BG2000四合一柔性化一體機(jī)

BG2000 is a four-in-one combination machine developed by Zhongchen Light Industry for flexible demand, which can simultaneously meet the production needs of glass bottles and aluminum cans for filling, filling and sealing (capping). The rated production capacity is 1800 bottles (cans)/hour. It is particularly suitable for small production needs of craft brewing and laboratory.

On a very small footprint, the combination machine integrates 12 bottle (can) washing machines, 9 filling machines, 1 capping machine, and 1 sealing machine; filling is achieved through pressure equalization filling with electronic valves; the touch screen makes it easy to adjust individual filling valves; the capping machine is also compatible with pull ring capping; the sealing machine uses servo control technology, which is efficient and reliable for roll sealing.

Recommended News

-

ABInBev Group visited Zhongchen Light Machinery

2025-03-15

-

Good News |Hefei ZhongChen(HF.ZCQJ)Honored with Carlsberg Group's "Outstanding Supplier" Title

2025-05-13

-

CBST 2025 Successfully Concludes: Zhongchen Light Machinery Shines on the "Digital, Intelligent, and Green" Stage

2025-03-07

-

CBST 2025 Successfully Concludes: Zhongchen Light Machinery Shines on the "Digital, Intelligent, and Green" Stage

2025-03-07

-

Fun Welcoming the New Year | Exciting and Thrilling! Zhongchen Light Machinery’s Sports Event Was a Blast!

2025-01-20

-

The governor of Anhui Province, Wang Qingxian, visited Zhongchen Light Machinery to investigate its digital transformation progress.

2024-12-10

-

CBB 2024 | Zhongchen Light Machinery Makes a Grand Appearance!

2024-11-27

-

CBB 2024 | Zhongchen Light Machinery Makes a Grand Appearance!

2024-11-27

-

"Eight Good" Goals Accelerate Implementation | Budweiser Equipment Supplier Strategic Alliance - Zhongchen Light Machinery & Budweiser Xinxiang VPO Launch Conference

2024-11-13

-

Zhongchen Light Machinery and CCH Coca-Cola Strategic Cooperation Kicks Off

2024-09-19